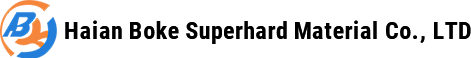

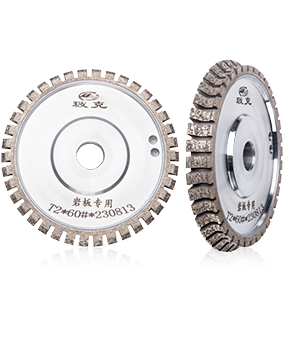

CNC Diamond Wheel

Classification:

Consulting

Consulting

Product Details

Bonding agent: diamond, bronze alloy, etc;

M specification size:

Diameter: 80-200mm.

Bore: 12/22mm;

Thickness: 2-18mm;

Grit: 80#-400#.

Service life over 20000 meters

Other specifications support customization

A CNC diamond wheel is a highly specialized cutting tool in the field of precision machining.

I. Composition and Structure

It is composed mainly of diamond particles, which are known for their extreme hardness. These diamond particles are bonded to a wheel substrate using a specific bonding material. The substrate provides the necessary mechanical strength to the wheel. The structure is carefully designed to ensure that the diamond particles are evenly distributed, allowing for consistent cutting performance.

II. Machining Applications

1. In the manufacturing of hard materials such as ceramics, carbide, and glass, the CNC diamond wheel is indispensable. It can achieve high - precision cutting with very narrow tolerances. For example, in the production of ceramic components for the electronics industry, it can create smooth edges and accurate shapes.

2. In the jewelry industry, it is used to cut and shape precious stones. The sharpness of the diamond particles enables the creation of intricate designs on gemstones with minimal material waste.

III. Advantages

1. High - precision: It can cut with a high degree of accuracy, which is crucial for components that require tight tolerances in industries like aerospace and medical device manufacturing.

2. Longevity: Due to the hardness of diamond, the wheel has a relatively long lifespan compared to other cutting wheels. This reduces the need for frequent replacements, thus saving costs in the long run.

3. Efficiency: It can remove material at a relatively high rate, increasing the overall productivity of the machining process.

In conclusion, the CNC diamond wheel plays a vital role in various industries that demand high - quality and precise cutting operations.

Key words:

CNC Diamond Wheel

RECOMMEND PRODUCT

ONLINE MESSAGE

If you have any suggestions, please leave a message or send an email to us, and we will reply to you within 1 working day after receiving the message email.

Get a Free Consultancy

If you have any suggestions, please leave a message or send an email to us.

No.1 Guhe Road, Xinsheng Industrial Park, Chengdong Town, Hai’an, Nantong, Jiangsu Province

CLASSIFICATION