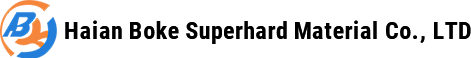

For Rock Slabs

Classification:

Consulting

Consulting

Product Details

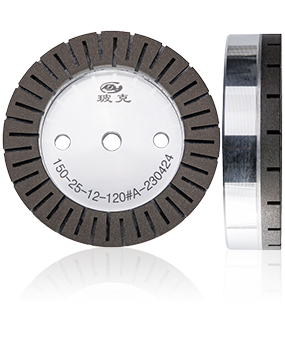

Bonding agent: diamond, bronze alloy, etc;

M specification size:

Diameter: 80-200mm.

Bore: 12/22mm;

Thickness: 2-18mm;

Grit: 80#-400#.

Service life over 20000 meters

Other specifications support customization

The rock grinding wheel is typically a circular disk with a central hole for mounting on a grinding machine. It is composed of abrasive grains, a bonding agent, and sometimes fillers. The abrasive grains are the key component responsible for the grinding action. Common abrasive materials used in rock grinding wheels include diamond, corundum (aluminum oxide), and silicon carbide. Diamond is the hardest known material and is especially effective for grinding hard rocks such as granite and quartzite. Corundum is a more affordable alternative and is suitable for many types of rocks, providing good abrasion resistance. Silicon carbide is known for its sharpness and is often used for fine grinding and polishing.

The bonding agent holds the abrasive grains together. Resin - based bonding agents are popular as they offer flexibility and good heat dissipation. Vitrified bonding agents are also used, which are more rigid and can withstand high - pressure grinding applications. Fillers may be added to improve the wheel's performance, such as increasing its strength or adjusting the porosity.

When the rock grinding wheel is in operation, it rotates at a high speed. As the rock comes into contact with the wheel, the abrasive grains on the wheel's surface cut into the rock through a combination of abrasion and chipping. The sharp edges of the abrasive grains remove small fragments of the rock, gradually shaping or smoothing it. The grinding process generates heat, which is dissipated through the bonding agent and the surrounding air. The efficiency of the grinding depends on factors such as the rotational speed of the wheel, the pressure applied, and the nature of the rock being ground.

Key words:

For Rock Slabs

RECOMMEND PRODUCT

ONLINE MESSAGE

If you have any suggestions, please leave a message or send an email to us, and we will reply to you within 1 working day after receiving the message email.

Get a Free Consultancy

If you have any suggestions, please leave a message or send an email to us.

No.1 Guhe Road, Xinsheng Industrial Park, Chengdong Town, Hai’an, Nantong, Jiangsu Province

CLASSIFICATION