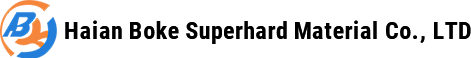

Diamond Four Edge Grinding

Classification:

Consulting

Consulting

Product Details

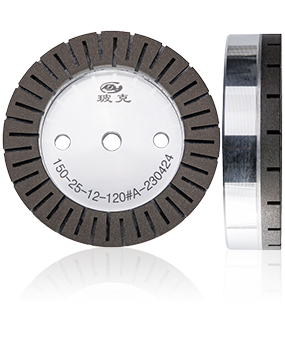

Bonding agent: diamond, bronze alloy, etc;

Diameter: 160mm.

Bore: 12/22/50mm;

Thickness: P10/P12/P20/P25/P30

Grit: 180#-320#

Other specifications support customization

In the world of precision machining and industrial fabrication, the choice of abrasive tool is paramount to achieving superior results. Among the various options available, the diamond grinding wheel stands out as a pinnacle of performance and durability. This tool, embedded with synthetic or natural diamond particles as its abrasive component, offers a suite of advantages that make it indispensable for working with the hardest and most challenging materials. The core benefits of utilizing a diamond grinding wheel are its exceptional longevity, its ability to maintain precision, its cost-effectiveness over time, and its superior performance on hard surfaces.

The most celebrated advantage of a diamond grinding wheel is its extraordinary lifespan. Diamond, being the hardest known material, exhibits minimal wear when grinding other substances. This extreme hardness means the wheel retains its form and cutting ability for significantly longer periods compared to conventional abrasive wheels made from materials like aluminum oxide or silicon carbide. This reduced wear translates directly into less frequent wheel changes, minimizing machine downtime and increasing overall operational efficiency. The longevity of a diamond grinding wheel is not just a matter of convenience but a major contributor to productivity.

Key words:

Diamond Four Edge Grinding

RECOMMEND PRODUCT

ONLINE MESSAGE

If you have any suggestions, please leave a message or send an email to us, and we will reply to you within 1 working day after receiving the message email.

Get a Free Consultancy

If you have any suggestions, please leave a message or send an email to us.

No.1 Guhe Road, Xinsheng Industrial Park, Chengdong Town, Hai’an, Nantong, Jiangsu Province

CLASSIFICATION